The CMMS inventory management software module in MaintSmart provides several useful capabilities that save the maintenance manager time while adding consistency to the spares usage for all maintenance management purposes. There are several ways to use spares on work orders, preventive maintenance, downtime and for unspecified equipment use. As follows:

- Work orders - manual linking of needed parts from the work order screen.

- Work order templates - automatic parts usage from previously linked parts lists when new work order created from template.

- Downtime - manual usage of parts against downtime instance. Note: usually makes more sense to link the parts for downtime to the repair work order instead of the downtime record.

- Preventive maintenance - use manually on-the-fly.

- Preventive maintenance - use automatically when PM is closed if linked parts list.

Link Spares to a Preventative Maintenance Task List

Spare parts may be linked to PMs. Parts may be simply listed or automatically used from stock when the PM is closed. Shortages and location of needed parts is listed on the preventative maintenance software task list. Parts automatically used may be easily returned from the parts usage screen.

Link a Required Parts List to a Work Order

Parts lists may be linked to a work order template and/or a work order. When linking to a work order the parts are simply used against this particular work order one time. Alternatively is parts are linked to a work order template these parts may be used on every new work order generated from the template.

Manual Part Usage

Parts may be manually used on-the-fly against either work orders, PMs, downtime or against any equipment item for no particular reason. The parts usage screen is quite flexible in providing a simple interface for using parts. User default may be set to so that common fields are populated automatically.

Work Order with Spares

Typically a work order is one primary task with detailed instructions, procedures or SOPs. This text may be up to 2GB of text per work order. Notice the parts list on this work order. Unlimited file attachments may also be added and best of all these attachments mat be any file type and may be set to automatically print with the work order.

PM List with Spares

The PM list may contain many preventive maintenance tasks each with its own associated spare parts list. Each task may have detailed instructions, procedures or SOPs of virtually unlimited length.

Other Useful CMMS Software Inventory Management Features

In some cases parts that have been already checked out from the parts storeroom will need to be returned. This is as simple as selecting the original parts usage record and decrementing the quantity used. The inventory store records are appropriately incremented by the same quantity (returned quantity) automatically so there is never a need to manually adjust the inventory data, other than when performing audit adjustments.

Linking a Parts List to a Preventive Maintenance List

Linking a Parts List to a Work Order

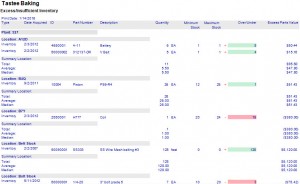

Inventory Management Audits and Reporting

The MaintSmart inventory management capability extends to auditing and extensive reporting.

Auditing capability included in version 4.1 uses physical inventory variance audit techniques to report on shortages and excesses. Version 5.0 continues with this method but also adds cycle-count audits and ABC analysis to the inventory management software module. As with all additions to the software if this new capability is needed by the maintenance manager then use it, otherwise ignore it.

For additional training and resources on the topic of CMMS inventory management software use the contact buttons on the right side of the screen to request a personal training session.