EAM software (EAM stands for enterprise asset management) is a comprehensive approach to asset management. While CMMS (computerized maintenance management software) is powerful when properly implemented for the management and maintenance of physical assets, EAM goes a step or two further. For example, EAM provides these additional benefits over CMMS:

- Inventory management.

- Purchasing management.

- Downtime analysis and management.

- Project management.

- Equipment Life Cycle tracking.

- Total Cost of Ownership.

Generally, to acquire an EAM software tool requires a larger initial investment than a CMMS. With MaintSmart this is not the case. Although MaintSmart is not a full-blown EAM it does provide most EAM features and functions without the added cost.

EAM Software or CMMS Software?

With all of the choices, how to I choose between a CMMS and an EAM? Should our organization use both concurrently? What are the differences between a CMMS and an EAM? How is MaintSmart different?

Choosing an EAM Software Solution

When is it best to choose an EAM over a CMMS? When you want more that just an equipment maintenance program an EAM might be appropriate. For example, perhaps you need to integrate an inventory management system along side the equipment maintenance program. This is often the case as it makes sense to have all equipment data in the same place. Drawing spares from the same software application that manages all other equipment assets (for work orders, preventive maintenance, downtime tracking, etc.) simplifies access to data and consolidates all of this related data in one place.

Additionally, now that all equipment data is in one EAM software application reporting and analysis becomes simpler and probably more accurate. In short, ease of access to needed CMMS reports, analysis and general day-to-day use of this system encourages buy-in from the potential end-users of the EAM. Lastly, costs play a role in software acquisition. Buying and maintaining one software system is generally less expensive than buying and maintaining two software solutions.

MaintSmart answers this cost question by providing most EAM capabilities in our CMMS software program.

MaintSmart CMMS = MaintSmart EAM

CMMS software is appropriate for maintenance of equipment assets. This maintenance usually includes preventive maintenance, work orders, inventory spares management and possibly downtime tracking in some of the more advanced CMMS solutions. In many, if not most cases a CMMS is perfectly adequate for the business goals related to asset management and especially maintenance. MaintSmart provides all of the above and additionally includes (with the base module) the following EAM software related modules:

- RFQ (request for quote) module.

- Complete role-based inventory requisition system.

- Purchasing management software.

- Asset depreciation module.

- Automated data collection and work order creation via OPC compliant equipment interfaces.

- Automatic reporting and work assignments based on calendar or event.

- Project management.

- Reliability analysis (military standard).

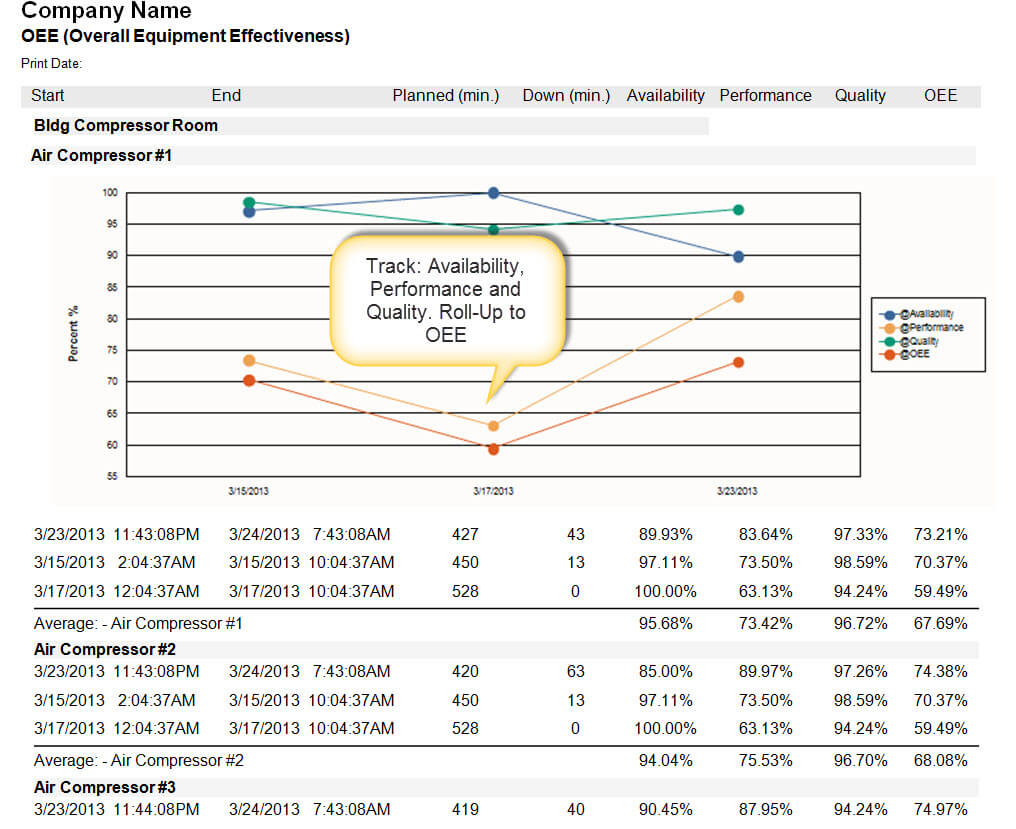

- OEE (overall equipment effectiveness).

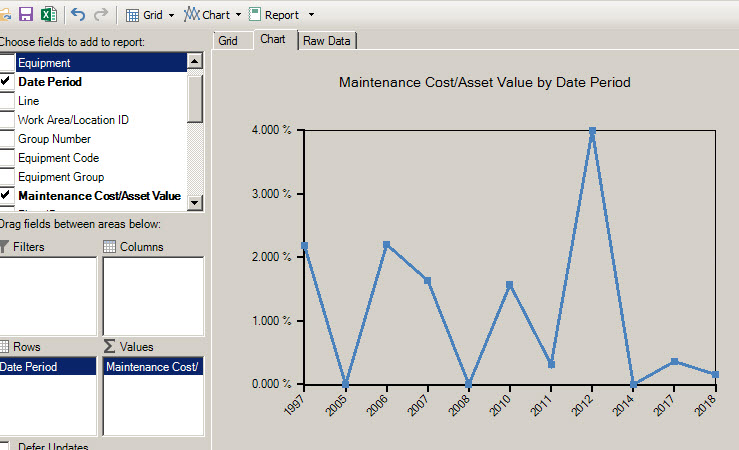

- Maintenance Cost vs. Replacement Asset Value.

- Much more...request a live demonstration to learn more!

EAM Software and Life Cycle

There are four (4) main components of Life Cycle that concern the maintenance manager as follows:

- Planning

- Acquisition

- Maintenance

- Disposal

The planning stage is accommodated by MaintSmart EAM Software with a Microsoft Project style scheduler and a work order system that provides for multiple work orders to build a major project work order. Additionally, acquisition is managed from request for quote RFQ, to requisition, requisition approval, purchase orders, retrieval and finally to invoice matching for all received purchases. This is a complete acquisition management solution that fits the EAM paradigm.

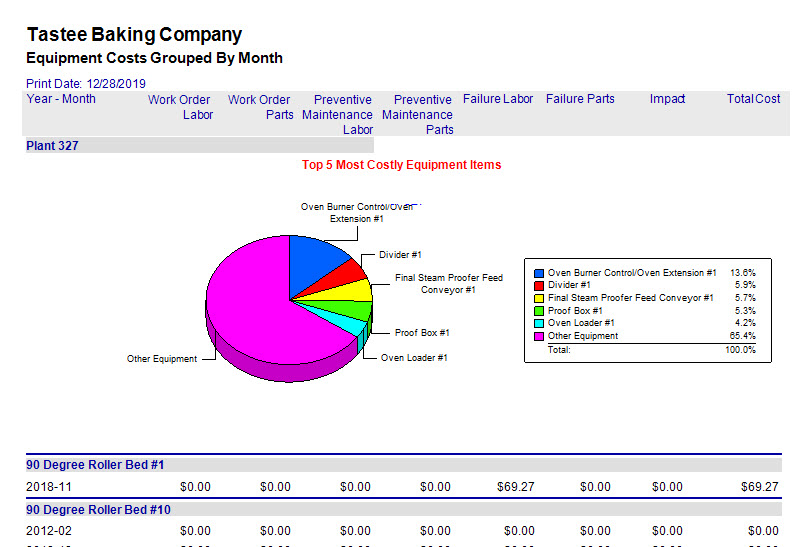

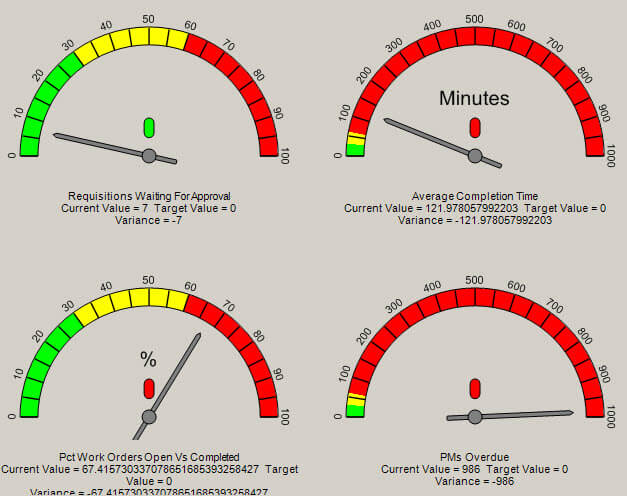

Next the maintenance stage, probably the longest stage, is handily managed by our CMMS capability. The EAM software manages work orders (manual or automated), preventive maintenance, downtime (equipment failures) and inventory management (including spares usage manually or automatically). Furthermore all of these modules have extensive reporting and analysis capability that also includes a powerful print and email CMMS work scheduler. Drag and drop to create powerful custom CMMS reports in seconds. Additionally, reliability analysis interfaces with the preventive maintenance module guiding the maintenance manager towards optimized preventive maintenance (PM) task lists. Lastly, OEE (overall equipment effectiveness), extensive analysis for all modules and 4 different ways to report round out an especially useful solution for the maintenance manager.

Contact Us! We want to hear from you.

- Free personalized online demonstration?

- Free help documents and videos?

- Formal quote or proposal?

- Free consultation?

MaintSmart Software, Inc., 66164 Homestead Rd., North Bend, OR, 97459 U.S.A.

+1-541-404-0616 ~ [email protected]