CMMS Frequently Asked Questions (FAQ)

Software Trial (Demo), Help Documents and Media

YES! We are available during normal business hours 8:00 AM to 5:00 PM Pacific Time (West Coast USA) and available after/before business hours by appointment. Our demonstration will only cover items of interest to you and is never a sales pitch. it is for your benefit so that you can understand how MaintSmart will save you a great amount of time and money.

Contact us now by: email: [email protected] ~ phone +1.541.404.0616.

It is highly recommended that you first participate in a online demonstration to get yourself oriented in how to install, navigate and benefit from the software. Follow this link to get the answer to this FAQ:

How Do I Download the Free Trial of MaintSmart CMMS Enterprise Software?

We have found that it is best to provide you with a personalized online demonstration of the software running on our server prior to giving you the software download link for self-evaluation. This benefits you in several ways:

- You will understand the capabilities of the software and how they integrate with each other.

- You will feel confident in navigating though the software.

- You will learn how to add and print work orders and preventive maintenance lists.

- Best of all you can ask any question and have our CMMS expert answer you immediately while demonstrating the answer online with the CMMS

Typically this personalized demo takes 15-30 minutes but it can be as long or short as you need to feel confident in the capabilities of MaintSmart . Please call, chat or reply to this email now to schedule your own personalized online demonstration of the software.

If you would still like to try out MaintSmart without a free online personalized demonstration we suggest you watch these YouTube videos first

1.) Learn the basics of logging in (YouTube Video): https://youtu.be/gxW2KbzTV_w

2.) More work order basics and printing work orders (YouTube Video): https://youtu.be/SvnHgMo27bc

3.) Reporting topics and options (YouTube Video): https://youtu.be/t7UxwRwAa54

This video link show how to quickly log in and create a work order once the DEMO software has been installed.

You Tube Link: Login for First Time - Create a Work Order

This YouTube video explains how to set-up an empty database (provided with the installation) and configure some equipment data.

The trial period for the full MaintSmart Enterprise software is 30 days. During the trial period you have full access to phone, webinar and priority email support. The MaintSmart Web solution is available for testing from our web site but does not have a trial version that you can install on your own server.

Yes! Many licensed MaintSmart user begin by first testing the software with one of the populated databases. Once they are comfortable with the navigation and feel of the system they add their own maintenance data into the empty database taht is supplied with the demo version of the software. This is a simple Access database that doesn't even require that you have Microsoft Access. Once the user licenses the software they can use the MaintSmart import utility to copy all the data over to a more robust SQL server database or keep using the same Access database.

Follow this link for the answer to this FAQ:

How Do I Download the MaintSmart User Manuals and Other Help Media?

Yes. A really good way to see the feature in action is to schedule your own personal online session with one of our maintenance experts. We will have the software running on our server and you can ask any question and have the answer demonstrated immediately.

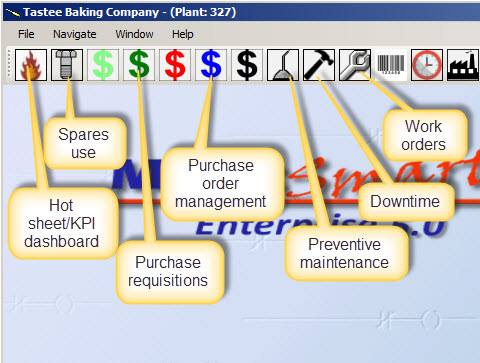

Basic CMMS Modules:

- Work orders and repair tickets.

- Preventive maintenance.

- Purchase requisition and purchase order management (complete solution)

- Inventory management.

- Equipment down time tracking.

- Analysis and reporting modules for all the above.

Additional Capability:

- Role-based permissions make it possible for everyone in your organization to use the software at some level.

- Equipment hierarchy gives you a way to group your equipment in a logical and intuitive way. This is used for filtering and reporting.

- Powerful report builder creates custom reports with chart of any data from every screen using intuitive drag and drop.

- Print and Email CMMS Scheduler automatically send date-sensitive PMs and other reports based upon user-defined schedule.

- Interactive personalized dashboard with drag and drop shopping cart and KPIs

- Event management system. Notifies users by email of various user-defined events. Example: Purchase requisition approved.

- Personnel scheduler (MS Project Style)

- Reliability Analysis (military standard) and OEE (overall equipment effectiveness)

- Powerful and flexible export formats: Excel, MS Word, Adobe and many more.

- Barcode scanning work orders, equipment, personnel and inventory spares.

- Extensive analysis modules for all main modules provides optimization recommendations to improve reliability and efficiencies.

Utilities and Other Useful Features

- Work requester capability provide an accountable way for non-maintenance personnel to request work directly to maintenance.

- Several search options by typing or filtering make locating the correct data simple and very fast.

- Duplication features for speeding up configuration of preventive maintenance task lists and more.

- Data row coloring for out of range items.

- Grouping of items for filtering and finding the correct items fast.

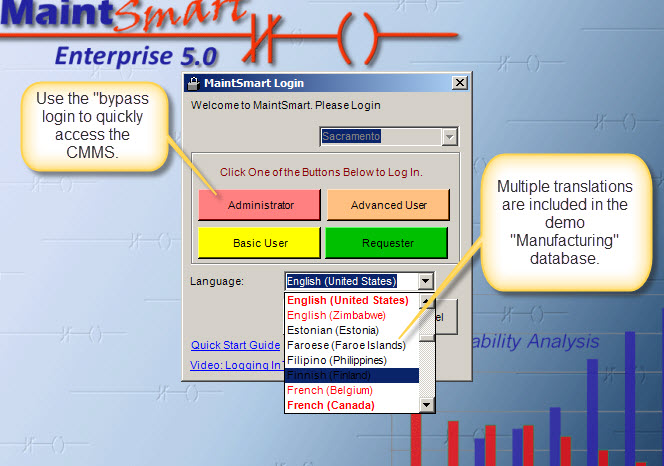

- Completely translatable into any language. Ten (10) translations provided in trial version.

- Two CMMS inventory management audit functions.

- All spares used are referenced to where used, why used and who used.

- Reliability analysis uses MTBF and Failure Rate to forecast % chance of equipment failing and to recommend PM task intervals to prevent failures.

- Overall Equipment Effectiveness (OEE) included in base program at no extra charge.

Reporting

- Crystal reports included with filterable detailed reports. Many have charts.

- MaintSmart report builder. This is a drag and drop report builder that works from any screen. Simple and very powerful.

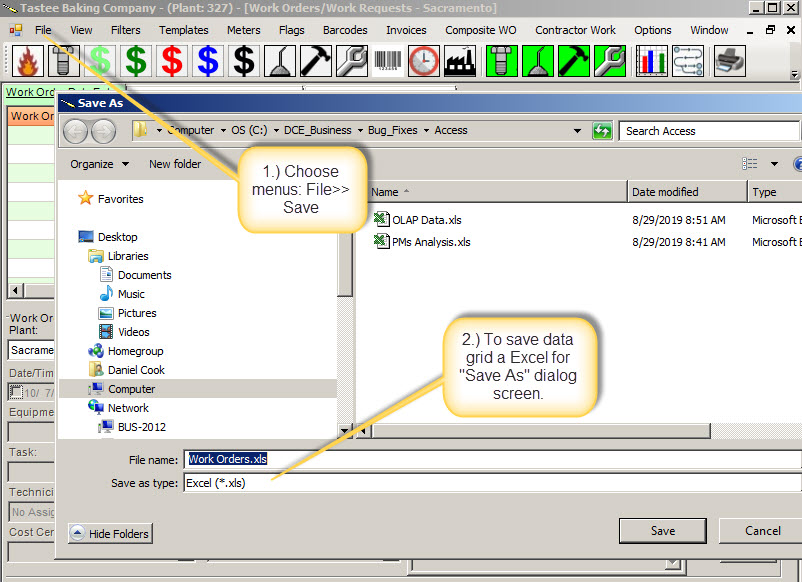

- MS Excel direct export. Every screen directly exports data to Excel then opens the new Excel file.

- Web page export (.html). All screen directly export all data and convert the data to a web page for you seamlessly. You can always share data with MaintSmart.

- MS Excel automation from analysis screens imports analysis data to Excel then builds statistics and a nice chart.

- Export formats: MS Word, MS Excel, Adobe Acrobat, all picture formats, many text formats and XML.

Software License and Support Options

- Option 1: Permanent License (MaintSmart Enterprise) is a one time purchase with no required fees of any type later and a perpetual license (lifetime license).

- Option 2: Monthly Subscription. This is MaintSmart Enterprise running on our Cloud server.

- Option 3: MaintSmart Web. This is a web add-on to the MaintSmart Enterprise solution (lifetime license).

- Option 4: MaintSmart Phone: cross-platform smart phone application (available late 2019).

- Extended Support (annual): chargeable but completely optional provides toll-free phone support, priority email support, free upgrades and free online trouble-shooting.

- Standard Support: free to all users forever include standard email support.

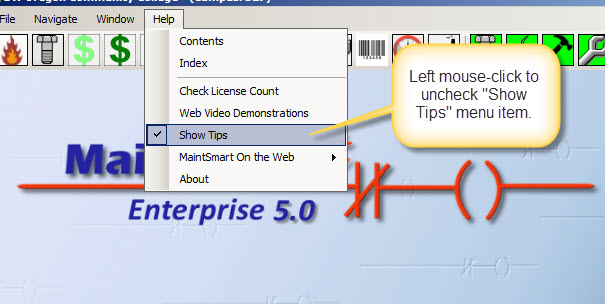

The trial version of MaintSmart uses bypass login buttons on the initial log in screen. These buttons are used for the trial version (demo) to make it very simple for software users to login without having to know the user name and password that would normally be needed to log in.

Normal Login Procedure

The normal login requires a user name and password to access the software. The user names and passwords are created by the MaintSmart administrator from the Program Configuration screen. Users are added to User Groups (roles). Permissions are set for each of the user groups by the administrator and the users in these groups inherit the permissions assigned to the group. Therefore changing the permissions in a group also changes the permissions for all users in that group. Additionally, the administrator can create their own custom groups and assign the contained permissions any way they choose. This provides virtually unlimited flexibility and creates a way that enables all personnel in your organization access to the software at some level.

Bypass Login

The bypass login feature provides the administrator the ability to create a button for each of the main user groups (Requester, Basic, Power user and Administrator). These buttons are linked to the user or your choosing. When a potential user clicks one of the bypass login button they are immediately logged into the software with the corresponding role. Although convenient, issue this creates is there is no way to determine who actually logged in. In reality probably the only bypass login that would ever be used in a live maintenance application would be the Requester bypass login.

Software Installation CMMS FAQs

Follow this link to get the answer to this FAQ:

How Do I Download and Install MaintSmart CMMS Software?

DEMO USER:

If using the trial version of MaintSmart simply choose the Manufacturing DEMO database from the Tip of the Day screen that appears when the program starts. If linking to a different database, such as would be the case in a production environment see the links below:

LICENSED USER:

This video explains how to change the database connection: Setting or Changing the MaintSmart Database Connection (Access or SQL Server)

Here is a document that also explains initial set-up of the database connection with some installation topis too.

Of course you can also call and we'll walk you through the database connection procedure.

This video instructs on how to connect a SQL Server database to the MaintSmart CMMS program. The biggest downfall in connecting is setting SQL Server permissions on the database itself. This is not covered in this video.

Software Options and Versions

MaintSmart Enterprise is the complete CMMS software solution. This is a PC-Based application that may also be installed on the Cloud.For local server installs the software is a one-time purchase and all modules are included. Email support is free for life. Personalized phone, Skype and webinar support is available too.

These modules include (but not limited to):

- Work orders

- manual or automated

- trigger by event, day, date, time or meter

- unlimited file attachments of any type file

- Preventive maintenance management

- automatic recycling of calendar-based PMs

- automatic issuance at exactly the right time (email/print)

- Inventory management

- minimum stock alert

- restock alert

- lead time

- automatic restock reports emailed/printed

- physical inventory variance audits

- cycle count audit

- countless reports

- spares usage by, who, what, when, where and why.

- Purchasing management

- RFQ

- inventory requisitions

- requisition approval management

- purchase orders

- inventory receiving (partial, full, returns, etc.)

- invoice matching

- Downtime tracking and management

- OEE (overall equipment effectiveness)

- reliability analysis

- pivot tables and charts

- countless reports (automated or manual)

- event notification based upon severity

How Do I Download and Install MaintSmart CMMS Software?

There is a web-based add-on for the MaintSmart Enterprise system. Here is a short video that describes this product.

Yes! There is a iPhone/Android version of MaintSmart that is used for work order management. It include GPS mapping to equipment items and much more.

See some of the MaintSmart Mobile CMMS features and request a live demo. Become a MaintSmart Mobile Beta tester!

Here is a post that describes all the various ways to deploy MaintSmart

Software Licensing FAQs

Follow this link to get the answer to this FAQ:

How Is a CMMS User License Defined (what is a user license) for the Enterprise Software?

DEMO USER:

Contact us for a link and instructions on how to test the MaintSmart Cloud product from our test cloud server.

+1.541.404.0616

LICENSED USER:

Unlike MaintSmart Enterprise (self-hosted) MaintSmart Cloud product is hosted by our professional hosting team at Virtual Office Systems. The licensing for the cloud is per concurrent (logged on) user. This product is subscription-based. Full unlimited support and upgrades are included. The MaintSmart Cloud is completely hosted, managed and secured. All you need to do is log in and start using it. Contact

MaintSmart Web (MaintSmart Web Work Requester) is a permanent license if self-hosted and a monthly subscription if hosted along with our MaintSmart Cloud product. Similar to MaintSmart Enterprise the licensing is per concurrent user.

It is important to understand that concurrent users are users from the entire user pool that are currently logged into MaintSmart and actively using it. Furthermore it is very important to understand that there are NO LIMITS on NAMED USERS in MaintSmart. This means that you can have an unlimited potential user pool each with their own log in (or shared login) credentials.

We do not offer a trial version of MaintSmart Web that you can self-host and test, however we do have a professionally offsite hosted version you can test with our sample data. Contact us for links and details on testing MaintSmart web. we can also provide pricing and more info on MaintSmart Web.

+1.541.404.0616

MaintSmart Mobile is currently available in Beta (March 2021). If you would like to test MaintSmart Mobile send a request and we'll send you back the needed link. Please specify iPhone or Android. MaintSmart mobile is designed to manage work orders and equipment from either iPhone or Android devices. The MaintSmart Mobile data is stored in the same SQL server database as is MaintSmart Enterprise and MaintSmart Web.

Yes, discounts up to and including free. Please send your request with details of your organization and intended use of the software. We also reserve the right to reject any requests.

Our software comes in four different platforms.

- MaintSmart Enterprise is the full software self-hosted with a permanent license.

- MaintSmart Cloud is the full enterprise software professionally-hosted offsite with a subscription-based license.

- MaintSmart Web is an add-on to either of the above enterprise solutions. It is a pure web application for basic work order, downtime and PM access. MaintSmart Web can be either a permanent or a subscription license.

- MaintSmart Mobile is a smartphone application for use on Android and iPhone platforms. (available end of 2019). The first roll-out is for equipment and work order management.

- We offer a 30 day (extendable) trial period of the complete MaintSmart Enterprise solution. During this time you have full unlimited support. many users begin building their production CMMS solution during this time and go live with the demo (unlicensed) version. Once the software is licensed they continue uninterrupted with the CMMS.

- There are no refunds since we offer extensive testing time, free support, free web instruction and other benefits prior to a purchase commitment and have not received a request for a refund.

Each of the above platforms is priced based upon its capability and whether it is permanent of subscription-based. For a no obligation quote on any of the above please contact us by email at [email protected]. Please provide the following information with your request:

- Name of company or organization.

- Type of company or organization.

- Expected concurrent (simultaneous) user count (named users are unlimited in any event).

- How many computers you intend to install CMMS on or is this an application server install.

- Expected CMMS budget (optional).

Call: +1.541.404.0616

Chat: https://direct.lc.chat/11081037/

Email: [email protected]

Software Configuration and Initial Data Entry

MaintSmart is designed to work in any equipment maintenance application. MaintSmart is used in manufacturing, hospitals, schools/colleges, municipalities, mining, food-processing, hospitality/hotels, military, etc. As such all literal data and text it the software may be translated to another language or your own language with different text. MaintSmart is the only software in existence that has this capability.

Our sample manufacturing sample database uses various conventions in naming and defines various functions as follows:

- Top-level of equipment hierarchy: Plant (such as a factory or manufacturing plant). This is often renamed and does not require a translation but is changed in the program configuration screen in seconds.

- Second/Third level of hierarchy is called Process. Process contains Line. This is often changed in a non-manufacturing setting to (examples): Building, Floor or possibly Coordinates, Site, etc. It is entirely up to you how you want to label the equipment hierarchy.

- Parallel Second Level: Work Area, Location, Area, etc.

- Personnel that are completing the work are labeled: Technicians, Maintenance Tech, Engineer, Mechanic, etc. This label can also be changed without a full translation in seconds.

- Equipment: refers to the machine or equipment item that is the target of work orders, preventive maintenance, downtime spares (inventory) usage and so on. All data in the MaintSmart program eventually points back the the equipment item. As such, equipment performance, maintenance and costs are easily quantified with MaintSmart is elegant CMMS reports with charts and sub-total data.

- Work order: a unit of work formally assigned. In some cases a work request or repair ticket is simply modified then elevated to full work order status. Work orders may be very detailed or very simple. Add images and unlimited file attachments of any type file. Automate the work order process with work order templates.

- Preventive maintenance: Preventive maintenance (PMs) may be generated as a work order from the work order software module. MaintSmart also provide a dedicated calendar-based preventive maintenance software module that is very fast to update and even recycle the assigned tasks and reassigned them automatically. We use the term PM screen to designate this module, although the program will also manage PMs through the work order screen too.

- Downtime: refers to unexpected or expected equipment failures, stoppages or under capacity conditions caused by any reason.

- Inventory: generally refers to spares used to repair or maintain equipment. However, we have customers that manage ingredient inventories and other collections of items with the inventory software module.

The equipment hierarchy is simply a way to group equipment into logical groupings. The software demo program (Manufacturing DEMO Database) uses a fairly popular hierarchy configuration that is widely used and accepted in the manufacturing community. This is fine, but MaintSmart is also widely used in the facilities maintenance sector as well. Hospital, hotel, resorts, farming, government, military and so on all use MaintSmart. As such, the equipment hierarchy labels must be easy to change for any maintenance application.

MaintSmart is unique to all other CMMS software systems available today in that the equipment hierarchy is three dimensional. This gives virtually unlimited capability for filtering, analysis and reporting of the maintenance data. Some users elect to group equipment by physical location and functional location. This configuration give the best possible reporting and filtering outcome for both maintenance planners and managers looking for performance KPIs.

Although it is best to request a personalized consultation (completely FREE) you can explore this document that explains in detail how to set-up your equipment and equipment hierarchy. Also, keep in mind that we perform equipment imports too that save time getting your CMMS system up and running.

Here are some equipment hierarchy examples that are currently in use:

- Plant

- Building

- Oil Rigs managed and maintained by maintenance service company

- College

- Resort

- Wind Farm

- Here is an example of a manufacturing plant CMMS configuration.

- Here is a school, college or university maintenance configuration that is widely used.

Here is a video that explains the equipment hierarchy.

This is entirely possibly, however, due to database relationships and specific data type this is best performed by our expert team. We can provide an Excel spreadsheet that has all the places needed to import your data. Additionally we always encourage personal consultation on data imports. In many cases with new MaintSmart users this can be performed by us at no charge (depending on how well the spreadsheet is filled out). Generally we import equipment and spares inventory lists.

Contact us for a free consultation and for a copy of the import Excel template:

Call +1.541.751.0450

Follow link below for a detailed answer with a video demonstration of this action.

General CMMS Use

The link below answers this question:

Follow link below for a detailed answer with a video demonstration of this action.

Follow link below for a detailed answer with a video demonstration of this action.

Follow link below for a detailed answer with a video demonstration of this action.

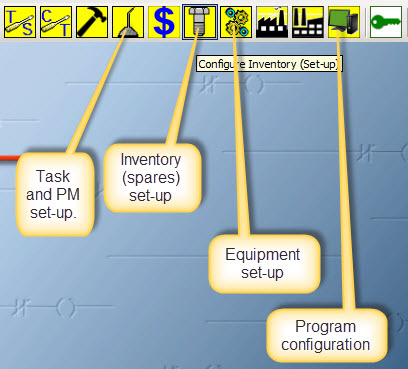

Navigation is done through the icons at the top of the screen. These icons are always available and multiple screens may be opened at the same time. The icons are color-coded on their background as follows:

- Light gray/white background: normal day-to-day use. Examples: create a work order, print a PM list, use a spare part.

- Green background: these button provide access to the analysis and reporting screens. Example: green background hammer is downtime analysis and reporting.

- Yellow background: these button are used for configuration of set-up. For example the yellow background bolt is for managing the spare parts list. The yellow background stacked gears icon is the equipment set-up screen.

- There are four buttons between the green and the yellow that are not color-coded. These buttons are for reliability analysis, equipment tree-view, print/email scheduler and meters.

Work Order FAQs

A work order is a unit of work. It can also be many different but associated tasks (composite work order). Work orders may be any type of work or notification that you need. This includes: preventive maintenance, projects, repair work, reminders, etc. Work orders are created by the following methods:

- Manually from the work order screen.

- Automatically by a meter event.

- Automatically by a calendar event (date/time).

- Automatically from the preventive maintenance screen.

- Automatically from the downtime screen.

- Semi-automatically from a work order template.

- Duplicated from the equipment tree.

- Duplicated from the work order screen.

- Converted from a repair ticket.

- From MaintSmart Web.

- From MaintSmart Mobile.

- From MaintSmart Cloud.

The links below answers this question in more detail:

What is a Work Order Template?

Follow link below for a detailed answer with a video demonstration of this action.

How Do I Add a New Work Order?

Follow link below for a detailed answer with a video demonstration of this action.

Can Work Orders Be Generated Automatically?

Preventive Maintenance (commonly asked questions)

Work Orders

Work orders are the basis for CMMS software. As with other packages all work can be created, assigned and managed from the MaintSmart work order screen. The work order screen has countless options that are used to embellish the work order if needed. These include unlimited file attachments of any file type, embedded images and unlimited text details. With that said a work order may be as simple as selecting 2 fields (equipment and task) thereby creating a new work order in seconds.

Calendar-Based Preventive Maintenance

The MaintSmart development team, through extensive research, determined that many preventive maintenance task list could be quite extensive with many tasks for each equipment item. Additionally it was determined that in most cases the majority of these tasks were performed on a day interval basis. For example: every 30 days, semi-weekly, weekly, annually and so on. As such we developed a CMMS module specifically for the purpose of calendar-based , relatively simple preventive maintenance (PM) task lists.

The beauty of the PM module is that these PM lists only need to be created one time. Thereafter whenever a PM is closed it regenerates a new PM automatically. It is true of work orders that they too can create themselves automatically, however in the case of PMs these are existing (not new) records that simply update to the new due date.

Follow link below for a detailed answer with a video demonstration of this action.

How Do I Change a Preventive Maintenance Task Interval?

Follow link below for a detailed answer with a video demonstration of this action.

Why Don't My Recently Added Tasks Show Up on the Preventive Maintenance Screen?

Below are four videos that explain each of the referenced topics. Preventive maintenance task list only need to be set-up once. Thereafter they recycle themselves on your defined PM interval.

Please watch these videos in order.

Down Time and Equipment Failure Tracking FAQs

Down time if the stoppage of an equipment item for any reason. This could be planned or unplanned downtime. Down time is not a work order. A corrective work order may be created to repair or restore equipment that has failed though. Down time is an instance of failure whereas a work order is a work assignment.

Down time is used by the CMMS to generate many statistical reports as well as Reliability Analysis and Overall Equipment Effectiveness.

Down time is generally thought of as an unexpected equipment failure but could also be planned down time. Additionally, equipment that is not running at capacity could be considered down time. MaintSmart offers unlimited user-defined down time types. There is extensive analysis and reporting tools that are available to locate and correct down time issues.

Learn more about equipment downtime.

Below is a video describing how to enter a new down time record..

The video below and this down time analysis link help to answer this CMMS FAQ.

Inventory (Spares) Management FAQs

CMMS FAQ: MaintSmart is a equipment maintenance management software program. As such, everything in the program ultimately points back to the equipment items.

What are equipment items?

Equipment items are generally machinery, fixtures, buildings and their components or any item that requires maintenance to prolong the equipment item's life and to improve reliability and availability of the equipment item. How you as a CMMS user decide to manage your equipment list is entirely up to you. In some cases managers like to call each large complete equipment items and all of it's component one equipment item. This makes sense in most cases.

For example suppose you have a conveyor to add to the equipment list. Should the conveyor be added as a complete unit or should its component parts be added each as individual equipment items? It is usually best to add a simple equipment items like this as one unit. This would include its conveyor chain, wear strip, motor, gearbox and motor control. When creating a preventive maintenance task list you could simply list the tasks as follows:

In the example above the various component parts of the conveyor are listed as part of the PM for this conveyor. Alternatively you could list each gearbox, drive, motor and so on as separate equipment items instead of spare parts of this overall equipment item (Conveyor #1). It is generally best to list the entire system as one equipment item instead of listing each component part as a separate equipment item. This makes the system much easier to manage. An exception would be one very large or complex equipment item that has component parts that perform specific functions within the overall equipment item.

What are spares?

Spares are spare parts (also called "inventory") used to maintain your equipment. Spares could be specific parts, fasteners in general, fluids or anything else used to maintain your facility and it's equipment. So of our users have even used the Inventory screen to manage ingredients. When spares are used they are linked to the following:

- where used (equipment)

- why used (work order, PM, downtime, etc.)

- who used

- when used

Spares may be of any user-defined type. By default they are listed as Inventory, however Non-Inventory, Consumables, etc. are commonly used types as well.

This inventory video explains adding an inventory item (spare) and other useful topic from the inventory software module.

Yes but due to database relationships and specific data type this is best performed by our expert team. We can provide an Excel spreadsheet that has all the places needed to import your data. Additionally we always encourage personal consultation on data imports. In many cases with new MaintSmart users this can be performed by us at no charge (depending on how well the spreadsheet is filled out). Additionally, we often import equipment lists so that you can immediately start benefiting from MaintSmart.

Contact us for a free consultation:

Call +1.541.404.0616

No, it is not necessary however these two modules do compliment each other and work very well together. For example if using the purchasing software module and receiving items from a purchase order (PO) these items automatically increment the quantities in the inventory database. Additionally partial receives are managed completely by the software as are returns.

Here is more information regarding the CMMS purchasing solution in MaintSmart. Also see the Purchasing CMMS FAQ on this page to learn how comprehensive and simple to use our requisition/approval/purchasing management system is.

Purchase Orders, Inventory Requisition, Requisition Approval and Invoice Matching

There are four ways to create a purchase requisition.

Yes, depending upon your user permissions you can create a purchase order directly.

Purchase requisitions may be approved, in the case where a very formal a secure purchasing process is desired. Requisition approval level are established for various qualified CMMS users. These level may be customized by you to perfectly fit your situation. Here are some hypothetical examples:

- Items under $500 require Level 0 permissions with 1 electronic signature.

- Items between $501 and $2500 require Level 1 permissions with 1 electronic signature.

- Items between $2501 and $10000 require Level 2 permissions with 2 electronic signatures.

- ...and so on. There are six level that you can customize and assign.

Once all items are approved on a purchase requisition the requisition can be immediately converted to a purchase order (PO), provide the user has Buyer permissions. These permissions can be assigned one to a user for the most secure purchasing system or you can assign 2 or more permissions to one or more users so that highly trusted user can create a PO directly without approvals, etc.

Learn more about approving purchase requisitions from this video.

Contact us for a free consultation:

Call +1.541.751.0450

No, it is not necessary however these two modules do compliment each other and work very well together. For example if using the purchasing software module and receiving items from a purchase order (PO) these items automatically increment the quantities in the inventory database. Additionally partial receives are managed completely by the software as are returns.

Here is more information regarding the CMMS purchasing solution in MaintSmart. Also see the Purchasing CMMS FAQ on this page to learn how comprehensive and simple to use our requisition/approval/purchasing management system is.

Reporting and CMMS Data Analysis FAQs

MaintSmart CMMS offers multiple ways to report. We also provide a powerful custom report builder that enables you to drag and drop any data you need and build beautiful statistical reports that include a custom chart. Additionally these reports may be exported to multiple formats for sharing with other users or for posting on your intranet as a web page.

This link provides information on several of the CMMS reporting methods available in our CMMS.

Below is a video that covers some of the reporting capabilities in MaintSmart:

Email servers are protected on your network so that virus programs and other unwanted senders cannot send email from your server without your express approval. As such, MaintSmart CMMS requires that you first set up your email configuration in the MaintSmart Program Configuration screen. This process should only be performed by your IT personnel or other qualified network technician.

Once the outbound (SMTP) email server has been configured MaintSmart will then be able to send out email as needed.

This video show the steps needed to complete this configuration.

Yes! MaintSmart has a powerful and flexible report scheduler. These reports can be virtually any report available in the CMMS. Here are some examples:

- Downtime for the weekend (with chart) where downtime was at least 10 minutes in duration.

- Preventive maintenance task list for John Smith that only includes his preventive maintenance coming due this week.

- New work order for daily checklist for the production department.

- Inventory items that need to be ordered today because they are below minimum stock.

- Monthly purchasing report of all closed purchase orders.

- Weekly preventive maintenance hours for each employee.

There are countless other reports and each report may be filtered to provide exactly what is needed. best of all, date sensitive reports use a floating date range so you only need to define your custom report one time. Thereafter the report always queries the correct data without any interaction from you.

These report are emailed to selected recipients or sent to designated printer(s).

The video below offers more detailed information on how the print/email scheduler works.

Contact us for a free consultation:

Call +1.541.404.0616

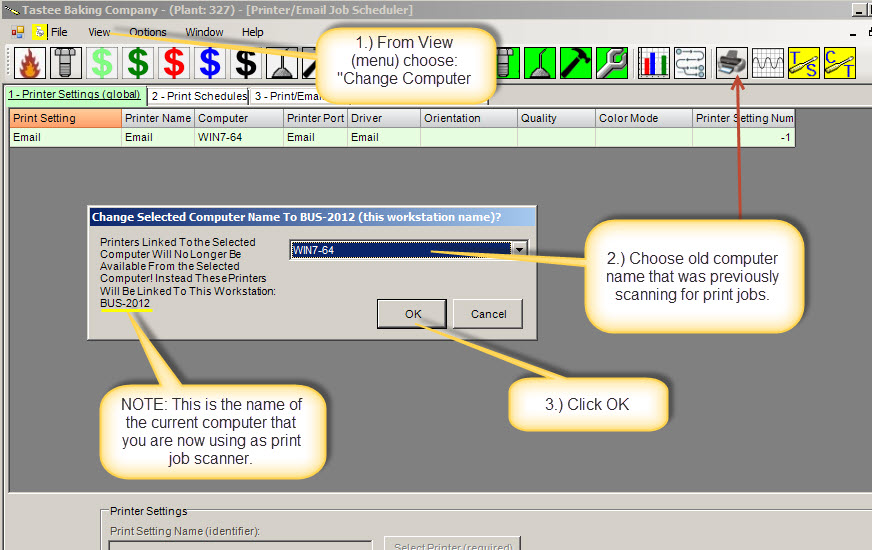

The print scheduler sends out printed documents automatically based upon your criteria and filters. This system is completely automated. Since the software is sending out print jobs to printers and these printers are connected to the computer that is generating (automatically) the print jobs, the print scheduler also needs to know the computer name. This prevents the print scheduler (if run from a different computer) from sending print jobs to either invalid or inaccessible printers. This applies to all printers accessible to the computer whether they are local or network printers.

When changing the name of the scanning and print job issuing computer or the entire computer for a new one, the computer name for the report scheduler must also be updated. This is very simple to do by simply choosing the name of the old computer name from the drop-down box to update to the new computer name as shown below.

Data Grid Options, Barcode Scanner and Other Utilities

Data Grid Options, Barcode Scanner and Other Utilities

- Barcode Scanner CMMS FAQs. How is that Done and What Scanner Should I Use?

- Why Don't New Equipment, Personnel, Vendors, Tasks and Failure Causes Show Up in the Drop-Down Boxes Immediately After I Add Them?

- I Need to Change the Default Sort Order to Show the Newest Work Order at the Top of the Data Grid. How Can that be Accomplished?

In most cases if a new data item (equipment, task, personnel, etc.) is added to a configuration screen while the screen that you intend to use the data item on is currently open the drop-down box doesn't show the new item unless manually refreshed. The reason for this is that the drop-down boxes generally have entries that are loaded from the database. If an item (example: new equipment item) is added from the Equipment Items screen the program does not automatically load drop-down boxes on screens that are currently open when the item was added. If it did reload the drop-down boxes every time a new data item was added your current addition or edit to the main target screen would be altered. Consider a network where multiple users re adding data to the same data table that loads the drop-down boxes you are working with on, for example, the work order screen.

So How Do New Entries Get Loaded Into the Various Drop-Down Boxes?

There are two primary time that data bound drop-down boxes get refreshed:

- When the screen target screen is opened (examples: work orders, downtime, inventory, etc.)

- The drop-down in question is manually refreshed without opening the target screen.

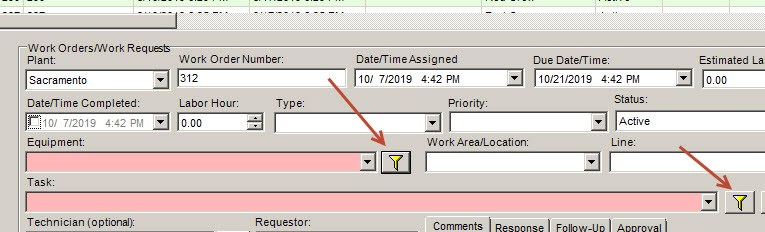

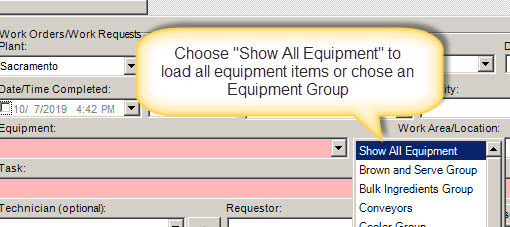

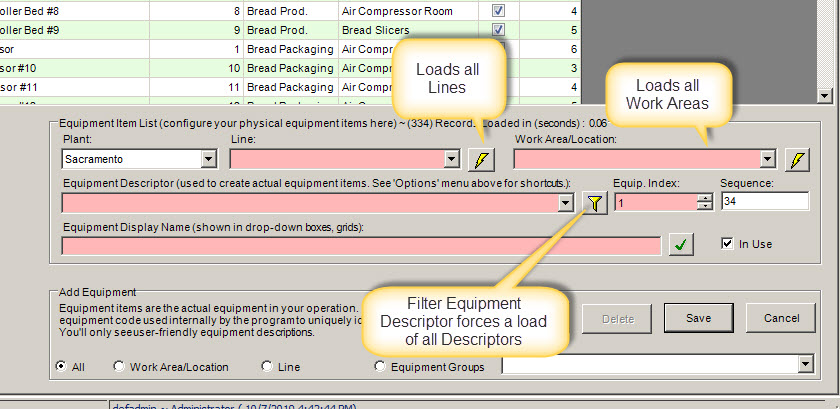

The first option is self-explanatory. The second option is generally available when you see the Yellow Funnel or Lightening Bolt button next to the drop-down. For example, if currently working on the work order screen and you leave the work order screen open to create a new equipment item when you return to the work order screen clicking the Yellow Funnel and choosing the Display All Equipment from the context menu all newly added equipment will load the drop-down box.

PLEASE NOTE: You DO NOT have to close and reopen the target screen to reload the main drop-down boxes.

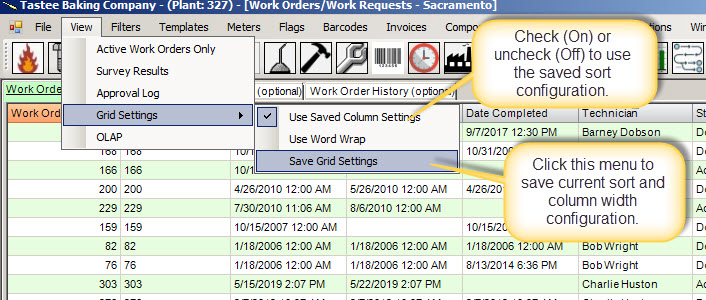

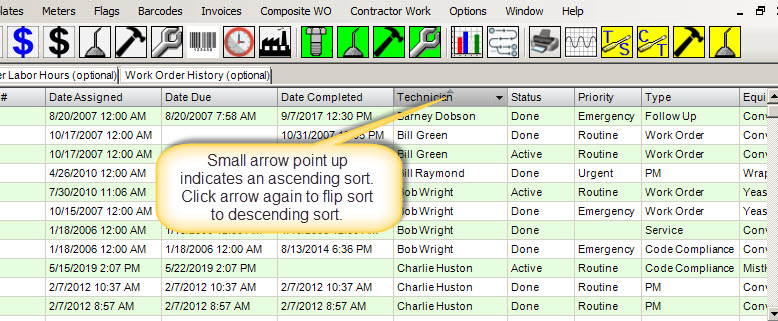

Data grids are arranged in rows and columns. Each column represents a field in the database. These columns can be sorted in ascending or descending order by clicking the center of the column header. It is also possible on the main screens to save the sort order, column width and hide columns completely. These settings are then saved to your user ID so that they come back whenever you open that particular screen.

The images below depict procedure to sort and save sort configuration.

Do You Have a Suggestion for Our FAQ Page? Please Submit Your Suggestion Below.

Your FAQ Suggestion Has Been Sent. Thank You!